Injection moulding design services play a significant job in transforming Tips into higher-top quality plastic pieces All set for mass manufacturing. Whether or not you happen to be building a new solution more than completely from scratch or bettering a pre-present part, Qualified style and design solutions Be certain that your moulded elements are economical to generate, Expense-productive, and meet performance anticipations.

What Are Injection Moulding Style and design Providers?

Injection moulding design expert services include the seem, engineering, and preparation of an aspect or item made for the injection moulding course of action. This contains sets from Preliminary 3D modelling and CAD (Computer system-Aided Design) drawings to prototyping and finalising mould style. The purpose is usually to produce a style and design that works well flawlessly with injection moulding equipment and operation, toughness, and aesthetic attraction.

Important Features of the Design Process

Various variables have to be viewed as when making for injection moulding:

Product variety: Deciding on the appropriate plastic is crucial. Diverse polymers offer special Houses, by way of example energy, overall flexibility, warmth resistance, or transparency.

click here Wall thickness: Uniform wall thickness helps prevent challenges like warping, sink marks, or incomplete mould fills.

Draft angles: Such as slight angles in the layout will help sections eject conveniently in the mould without the need of destruction.

Ribs and managers: These capabilities insert power and assistance to components with out increasing product utilization or excess weight.

A well-built aspect not merely increases functionality as well as cuts down manufacturing prices and cycle instances.

The worth of Professional Designers

Performing possessing an knowledgeable injection moulding structure team assures your products is prepared for successful producing. These industry experts comprehend the complexities of toolmaking, generation machining, and elements science, and In addition they should help refine your structure to stop highly-priced problems in the future.

Providers like Australian Consolidated Plastics supply entire style-to-generation expert services. Their in-residence staff takes advantage of Superior application to model precision applications and dies, guaranteeing each ingredient meets restricted tolerances and high-quality benchmarks. This comprehensive-support technique saves time, enhances precision, and accelerates time for you to marketplace.

From Prototype to Output

Design providers can direct you to definitely prototyping To judge kind, suit, and function before whole-scale production starts. This enables clients to acknowledge and hook up problems early, saving both equally time and funds within the long run.

Conclusion

Injection moulding layout services can be quite a critical step within producing journey. By buying clever, economical design and style, corporations can make certain their plastic factors are generation-Prepared, Expense-effective, and built to previous. With the correct design and style lover, your concept might be a industry-Completely ready actuality.

Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Yasmine Bleeth Then & Now!

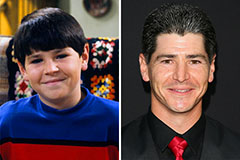

Yasmine Bleeth Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!